Introduction

In manufacturing, CNC (Computer Numerical Control) machine tools have revolutionized how complex parts are fabricated. These powerful machines deliver accuracy, efficiency, and productivity, enabling manufacturers to meet the demands of modern-day production. However, like any intricate machinery, CNC machine tools require regular maintenance to ensure optimal performance and longevity.

Table of Contents

This blog post will delve into daily maintenance for CNC machine tools. We will explore the fundamental steps, best practices, and tips for running your machines smoothly. By implementing a well-defined maintenance routine, you can minimize downtime, reduce costs, and extend the lifespan of your CNC machine tools.

Understanding the Importance of Daily Maintenance

Daily Maintenance Checklist

Visual Inspection

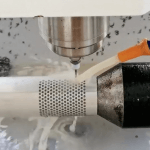

Conduct a visual examination of the machine, including the coolant system, chip conveyors, way covers, and safety guards. Look for signs of damage, leaks, loose connections, or foreign objects.

Cleanliness

Thoroughly clean the machine, removing chips, dust, and coolant residues. Consider critical components such as the spindle, tool changers, way covers, and linear guides.

Lubrication

Lubricate all necessary components as per the manufacturer’s recommendations. Check oil levels, replace filters, and ensure proper axes, ball screws, and bearings lubrication.

Coolant System

Inspect and maintain the coolant system, ensuring the proper level, clarity, and pH balance. Clean or replace filters regularly to prevent clogging and ensure optimal cooling and lubrication.

Electrical Connections

Verify the integrity of electrical connections, cables, and wiring. Look for loose connections, signs of wear, or damage. Ensure proper grounding for safety purposes.

Tooling

Inspect the tooling components, such as cutting tools and holders, for damage or wear. Replace or repair as necessary to maintain precision and efficiency.

Software Updates

Check for software updates or patches provided by the machine’s manufacturer. Keeping the control software updated ensures improved performance, bug fixes, and added functionalities.

Best Practices for Daily Maintenance

Training and Documentation

Provide comprehensive training to machine operators and maintenance personnel on daily maintenance procedures. Document the maintenance routine, including step-by-step instructions and timelines, to ensure consistency and accountability.

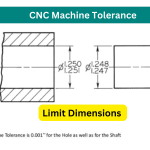

Regular Calibration

Calibrate the machine tools to maintain accuracy and precision. Follow the manufacturer’s guidelines for calibration intervals and procedures.

Monitoring and Data Analysis

Utilize monitoring systems and sensors to track machine performance, collect data, and identify anomalies or patterns. Analyze the data to address potential issues before they escalate proactively.

Safety Precautions

Prioritize safety by adhering to lockout/tagout procedures, wearing appropriate personal protective equipment (PPE), and maintaining a clean and organized work environment.

Collaboration with Suppliers

Foster a strong relationship with machine tool suppliers and manufacturers. Seek their expertise for technical support, troubleshooting, and guidance on specific maintenance requirements.

Troubleshooting Common Issues

Excessive Vibration or Noise

Poor Surface Finish

Verify tool condition, feeds, and speeds. Consider tool replacement, toolpath optimization, or tool wear compensation adjustments.

Tool Changer Problems

Clean and lubricate the tool changer mechanism. Inspect for damaged or worn components. Follow manufacturer instructions for troubleshooting specific issues.

Alarm Messages

Attention to the alarm messages on the machine’s control panel. Consult the machine’s manual or contact technical support for guidance on troubleshooting specific alarms.

Couclusion

Incorporate daily maintenance as an integral part of your production process, and your CNC machine tools will continue to deliver exceptional results for years.