CNC (Computer Numerical Control) machines are powerful tools in various industries to automate manufacturing processes. To ensure their longevity and optimal performance, regular maintenance is crucial. Monthly maintenance plays a significant role in preventing major breakdowns, minimizing downtime, and maximizing the lifespan of CNC machines. This quick guide will outline the essential steps for monthly maintenance to keep your CNC machine in top shape.

Table of Contents

Cleaning and Lubrication

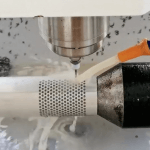

One of the fundamental tasks in monthly maintenance is cleaning and lubricating the CNC machine. Begin by removing debris, chips, or coolant residue from the machine’s surfaces, including the worktable, tool holders, and spindle. Use compressed air, brushes, or vacuum cleaners to remove the particles effectively.

Next, focus on lubrication. Refer to the manufacturer’s guidelines to identify the specific lubrication points on your CNC machine. Apply the appropriate lubricants to the designated areas, such as linear guides, ball screws, and tool changers. Ensure you use high-quality oils recommended by the manufacturer for optimal performance and longevity.

Inspection and Calibration

Regular inspection and calibration are vital for maintaining accuracy and precision in CNC machines. Examine the machine’s mechanical components, such as the spindle, bearings, belts, and pulleys. Look for signs of wear, damage, or misalignment. Tighten loose connections and replace any worn-out parts to avoid further complications.

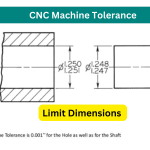

After inspecting the mechanical components, move on to calibrating the machine. It involves verifying and adjusting the accuracy of the machine’s positioning and cutting tools. Use precision instruments, such as dial indicators or laser alignment tools, to ensure the device is within the specified tolerances. Make any necessary adjustments according to the manufacturer’s guidelines.

Software Updates and Backups

The software running on your CNC machine also requires regular attention. Check for any available updates or patches provided by the manufacturer. Keeping the software up to date ensures you benefit from bug fixes, performance improvements, and new features. Follow the manufacturer’s instructions to install the updates correctly.

Additionally, it is crucial to regularly back up the machine’s software settings, tool libraries, and programs. This precautionary measure ensures that you can quickly recover in case of a system failure or accidental data loss. Back up the data onto external storage devices or use cloud-based solutions for added security.

Spindle Maintenance

The spindle is a vital component of a CNC machine, responsible for rotating the cutting tool at high speeds. Monthly maintenance of the spindle helps prevent premature wear and breakdowns. Begin by removing the spindle cover and inspecting the spindle for any visible signs of wear, damage, or contamination.

Clean the spindle using a non-abrasive cloth and an appropriate cleaning solution recommended by the manufacturer. Take care not to introduce excessive moisture into the spindle. Inspect and replace worn or damaged bearings as necessary, following the manufacturer’s guidelines. Finally, apply the recommended lubricant to the spindle at specified intervals.

Electrical System and Wiring

The electrical system of a CNC machine requires attention to ensure safe and reliable operation. Inspect the wiring for any signs of damage, loose connections, or overheating. Tighten loose connections and replace any frayed or worn-out wires promptly. Pay particular attention to the cable carriers, ensuring the cables move smoothly without any obstruction.

Check the condition of the electrical components, such as relays, fuses, and circuit breakers. Replace any faulty parts and ensure that the electrical system is grounded correctly. Be cautious when working on electrical systems, and always follow the safety procedures outlined by the manufacturer.

Regular monthly maintenance is essential for maximizing the lifespan and performance of CNC machines. By following the steps outlined in this quick guide, you can significantly reduce the risk of breakdowns, minimize downtime, and ensure the accuracy and precision of your CNC machine. Remember to refer to the manufacturer’s guidelines for specific instructions tailored to your machine model. Investing time and effort in monthly maintenance will ultimately improve productivity and cost savings in the long run.