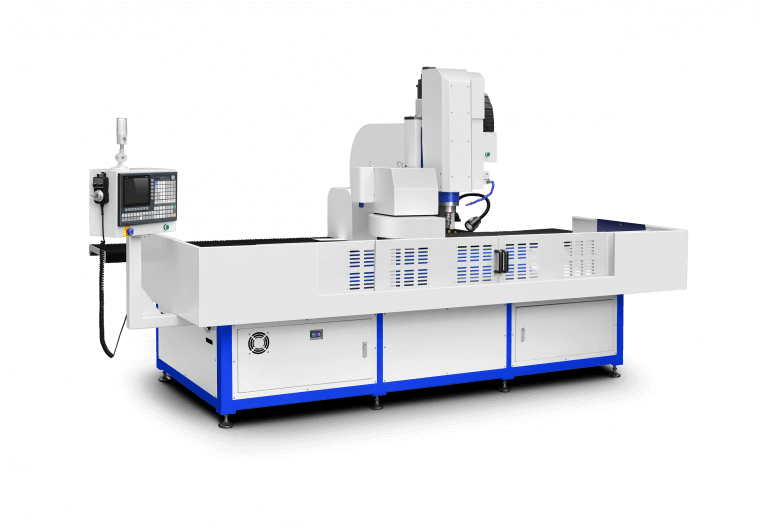

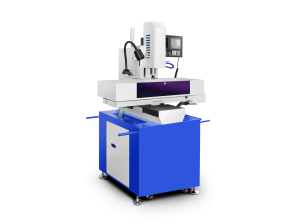

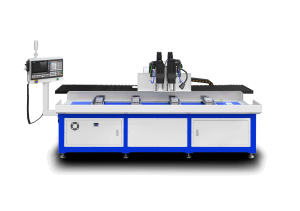

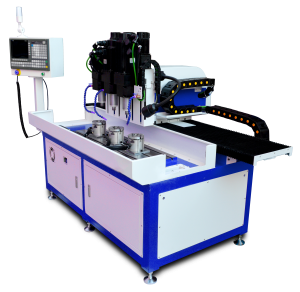

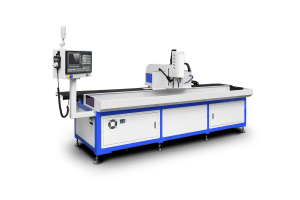

- Multifunctional automatic tools change flow drilling and tapping equipment, and they can also be used as common drilling equipment.

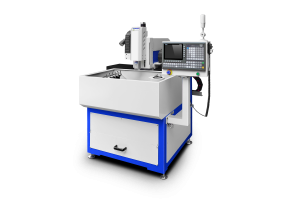

- The machine body has undergone structural strengthening treatment, with small vibration and strong stability.

- Optional self-contained guide rail type pneumatic tooling is convenient for clamping, fast for product switching and clamping, and improves work efficiency.

- Equipped with a spindle following the tool magazine, the servo is directly connected to the tool change action, which is convenient and time-saving for tool change

- Detected and compensated, corrected by the laser interferometer imported from the United States (API).