Introduction

Drilling holes in tubes may seem straightforward, but achieving accurate and clean results requires precision and attention to detail. Whether you’re working with metal, plastic, or any other material, understanding the techniques and tips for tube drilling is crucial. We will explore in this guide the key considerations and provide you with valuable information to enhance your drilling skills. Following these tips, you can create perfect holes in tubes for various applications, from plumbing to construction.

Table of Contents

Choose the Right Drill Bit

Selecting the appropriate drill bit is essential for achieving precise holes in tubes. Consider the material of the tube, its thickness, and the type of hole you want to create. Twist drill bits are commonly used for softer materials like plastic or wood. However, tougher materials like metal, carbide-tipped, or cobalt drill bits are more suitable. The bit’s diameter should match the desired hole size, ensuring a proper fit for screws or fasteners.

Secure the Tube

Before drilling, securing the tube firmly is vital to prevent it from moving or spinning during the drilling process. It can be accomplished using clamps or a vise, depending on the size and shape of the tube. Ensuring stability minimizes the risk of errors and produces accurate holes.

Marking and Centering

Marking the drilling point accurately is critical for precise hole placement. Use a center punch or a sharp awl to create a small indentation at the desired spot. It helps prevent the drill bit from wandering when starting the hole. Additionally, using a center finder or a square ensures the drilling point is aligned correctly and perpendicular to the tube’s surface.

Lubrication and Cooling

Lubrication and cooling are vital in tube drilling, especially when dealing with metals. Applying cutting oil or a suitable lubricant reduces friction and heat buildup, extending the life of the drill bit and promoting cleaner cuts. For larger or deeper holes, periodically withdraw the bit to clear away chips and apply more lubricant to prevent overheating.

Drill Speed and Pressure

The speed and pressure applied during drilling significantly impact the quality of the hole. When drilling through metal, using a slower rotational speed prevents overheating and extends the lifespan of the drill bit. Adjusting the pressure applied allows for better control and helps avoid drilling too quickly, which can lead to rough or jagged holes. Experiment with different speeds and pressures on scrap material to determine the optimal settings for your specific application.

Proper Chip Management

Managing the chips or shavings produced during drilling is crucial for maintaining a clean workspace and preventing tube or drill bit damage. Use a brush or compressed air to clear away chips regularly, ensuring they don’t interfere with the drilling process or accumulate around the hole.

Safety Precautions

Safety should always be taken into consideration when working with power tools. Wear appropriate personal protective equipment, such as safety goggles and gloves, to protect yourself from debris or potential accidents. Ensure the work area is well-ventilated to avoid inhaling any dust or fumes. Familiarize yourself with the drill’s operation and follow the manufacturer’s guidelines for safe usage.

Conclusion

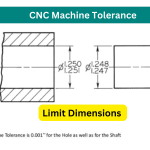

Mastering tube drilling requires a combination of proper technique, the right tools, and attention to detail. Following the tips outlined in this blog, you’ll be well-equipped to achieve accurate and clean holes in tubes for various applications. Select the appropriate drill bit, secure the tube firmly, mark and center accurately, and use lubrication and cooling for optimal results. Maintain a steady drill speed and pressure, manage chips effectively, and prioritize Safety at all times. Our DOBEMY auto CNC tube drilling machine is better than others, it’s very easy to operate, and no burr.