Stairway to Productivity: How StairSupplies Uses Flowdrill to Meet Growing Demand!

StairSupplies, which employs over 230 people at six production facilities in Indiana, StairSupplies, a well-known stair part manufacturer, has been seeing a surge in demand for its metal stair parts and systems, specifically its Viewrail range. To keep up with increasing orders and tight customer deadlines, StairSupplies invested in an automated Flowdrill technology to improve their production efficiency and throughput.

Table of Contents

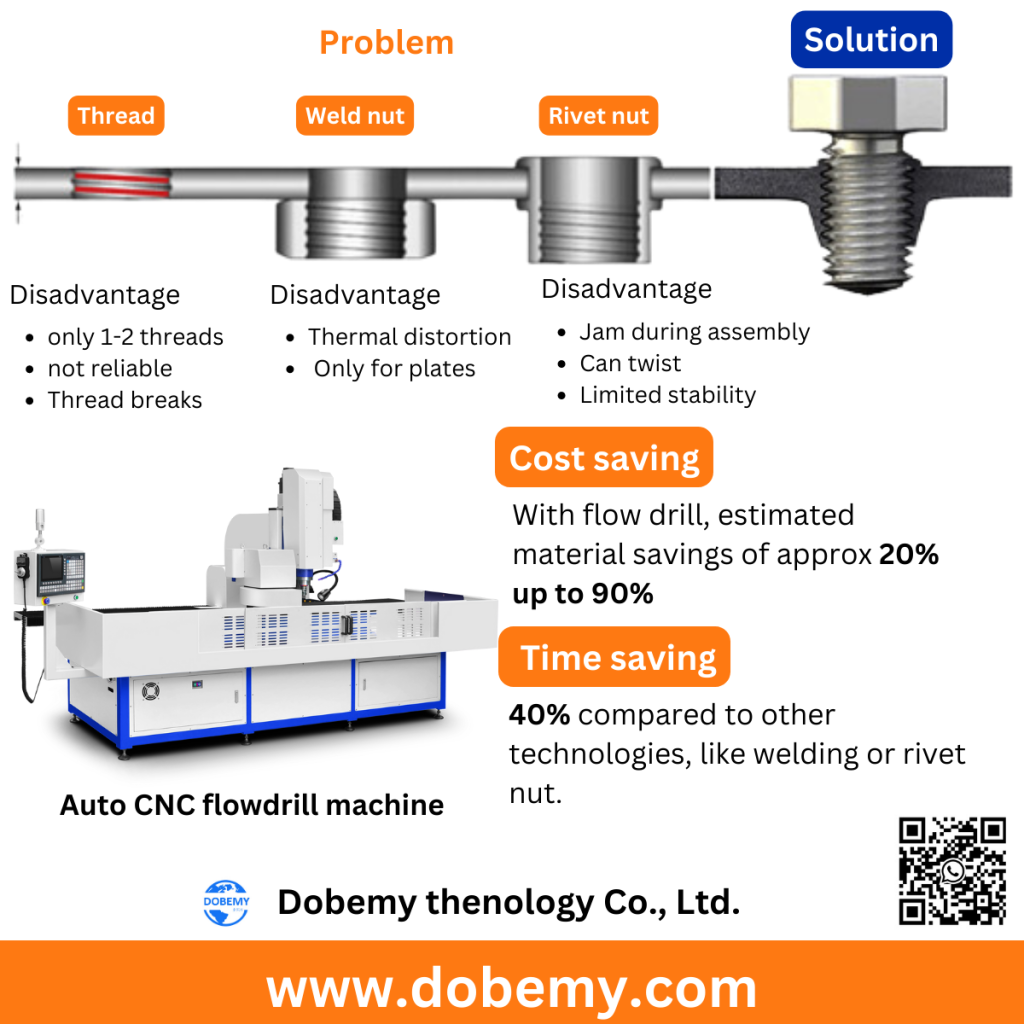

One of the critical challenges faced by Stair Supplies was the need to drill holes in their stair parts quickly and accurately. Traditionally, this was done using conventional drilling methods, which were time-consuming and required high skill to achieve the desired results. With the growing demand for their products, Stair Supplies needed a faster and more efficient way to drill holes in their stair parts.

Enter Flowdrill a revolutionary new drilling technology that has been gaining popularity in the manufacturing industry in recent years. Flow drill is a patented process that uses a solid carbide tool to create a bushing in a workpiece. The bushing is then tapped to create a thread, which can be used to attach various components to the workpiece. The process is fast, efficient, and highly accurate, making it an ideal solution for companies like Stair Supplies that must drill many holes quickly and precisely.

StairSupplies began using Flowdrill in their production process in 2018 and quickly saw the benefits of this innovative technology. The company reduced the time it took to drill holes in their stair parts by more than 50%, allowing them to increase production and meet growing demand without sacrificing quality. In addition to being faster than traditional drilling methods, Flowdrill also produces cleaner and more accurate holes, reducing the need for rework and improving the finished product’s overall quality.

Key Advantages of Flowdrill technology

One of the key advantages of Flowdrill technology is its versatility. The technology can drill holes in various materials, including steel, aluminum, iron, stainless steel, etc. It is an ideal solution for Stair industry that work with multiple materials in their manufacturing process. By using Flowdrill, Stair Supplies was able to streamline its production process and reduce the need for multiple drilling machines, which saved space and reduced overhead costs.

Another advantage of Flowdrill CNC machine is its ease of use. Unlike traditional drilling methods, which require a high degree of skill and experience to achieve the desired results, Flowdrill is a straightforward process that operators of all skill levels can easily master. It made it easy for Stair Supplies to train their staff to use and integrate the new technology into their existing production process.

In addition to the benefits of Flowdrill itself, Stair Supplies also appreciated the level of support and service provided by the technology’s manufacturer, Flowdrill Inc. The company worked closely with Stair Supplies to ensure they had the right equipment and tools to meet their specific needs and provided ongoing training and support to ensure the technology was being used effectively.

Since implementing Flowdrill technology in their production process, Stair Supplies has seen a significant increase in productivity and efficiency. The company can now produce more stair parts in less time, allowing them to meet growing demand and expand its business. By using Flowdrill technology, Stair Supplies has been able to stay ahead of the competition and maintain its reputation for quality and innovation in the industry.

Overall, adopting Flowdrill technology has been a game-changer for Stair industry. IT overcame the challenges of drilling holes in its stair parts and increased production efficiency to meet growing demand. By embracing innovation and new technologies, Stair industry has positioned itself for continued success in the years to come.